Machine Preventive Maintenance: Troubleshooting Water Dilutable Fluids

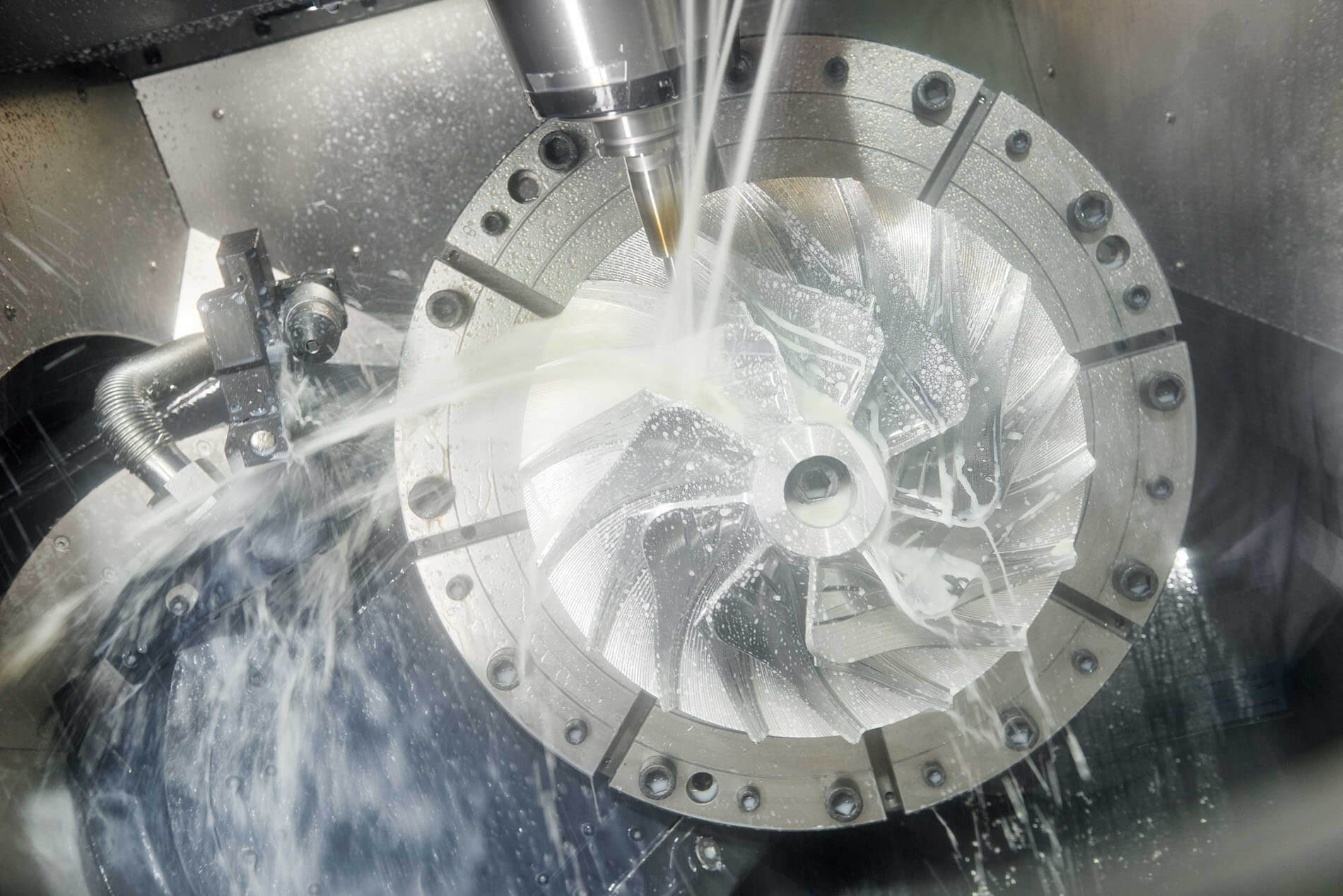

In a typical machine shop, the need to increase productivity and reduce costs has brought a much-needed focus to the importance of using the right metal cutting fluids. After all, cutting fluids typically cost 1/10 of the tooling they protect. Therefore, maintaining your machine coolant properly is a low-cost way to help extend tool life.

When manufacturing facilities have concerns about machine performance, the lubricant is often blamed. However, tests generally show that the problem isn’t the lubricant itself, it’s the way the coolant in the sump is maintained. Approximately 95 percent of most fluid systems are water. Therefore, water quality and concentration are critical (and often overlooked) aspects of cutting fluid performance.

Machine preventive maintenance tip 1: use the best water/coolant mixture. While you might not have any choice in your water, you do have a choice in fluids. Before selecting a fluid, your water should be tested in a lab and analyzed against the various properties of the available fluid solutions to be sure the fluid matches your manufacturing needs as well as the chemistry of your water source.

Machine preventive maintenance tip 2: mix coolants properly. The first rule in mixing metalworking fluids is that you always add fluid concentrate to water – not the other way around. This ensures the emulsifiers will properly suspend the oil in water. Remember: OIL = Oil In Last.

Machine preventive maintenance tip 3: concentration check. Using an optical or digital coolant refractometer, check the concentration of coolant at the beginning of every day or shift. Use the reading to carefully measure the amount of coolant or water needed to balance the fluid. Do not approximate. Unbalanced fluids can lead to foaming, odors, or excessive wear on your valuable tools.

Machine preventive maintenance tip 4: pay attention to pH. It’s important to know the normal operating parameters of your coolant so you can spot potential issues quickly. Low pH can lead to bacteria growth or signal low coolant concentration. High pH usually signals cleaner contamination.